HOME/Products/Motor & Coil Fab Equipment

Motor & Coil Fab Equipment

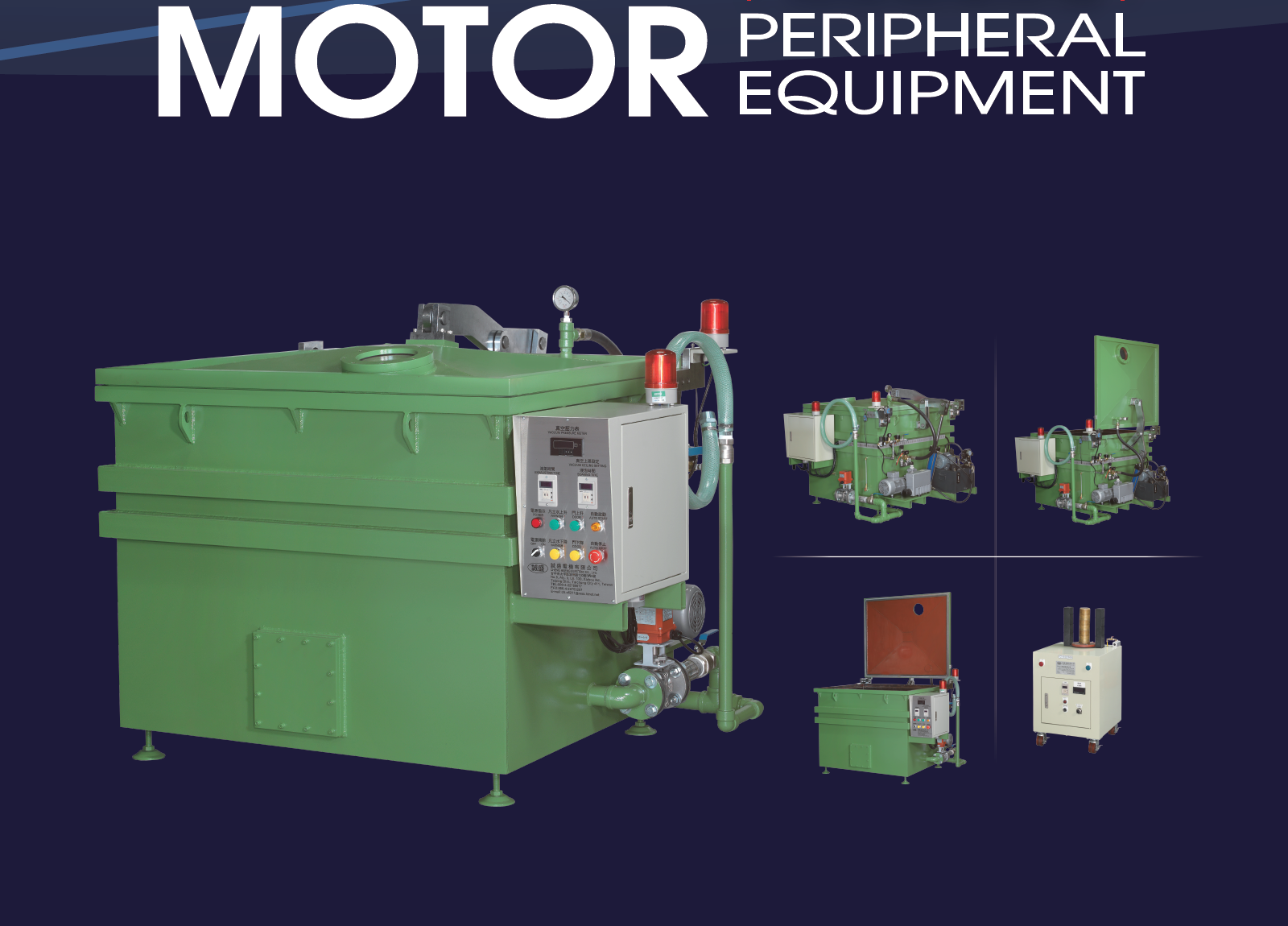

Motor Transformer Stator Coil Pneumatic Armature Varnish Dipping Machine

The Motor Transformer Stator Coil Pneumatic Armature Varnish Dipping Machine is engineered for precision coating of stator coils and armatures. Ideal for motor manufacturing and repair applications, it ensures uniform varnish coverage to enhance insulation and durability. The system supports controlled dipping cycles, minimizing waste and improving process consistency. Its robust design suits both small-scale workshops and industrial production lines.