Torque Motor

Torque Motor

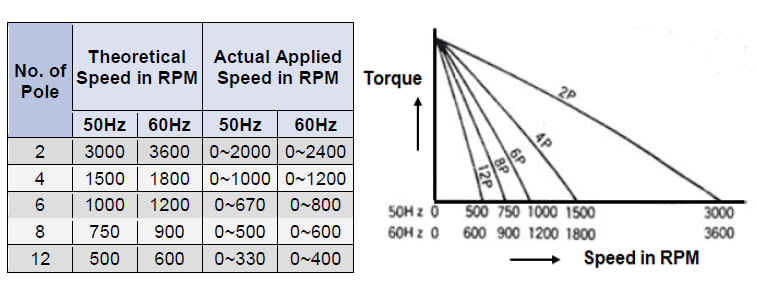

Torque motors are uniquely designed to deliver high starting torque and maintain stable operation at low speeds or under constrained load conditions. Unlike general-purpose motors, torque motors provide maximum continuous stall torque at zero speed, with torque gradually decreasing as speed increases to maintain balance between the motor and the load.

One of the key features of a torque motor is its ability to maintain constant torque even during low-speed operation or when the rotor is locked. The rotation speed can be adjusted by varying the supply voltage, allowing precise control in applications where constant torque is required. When the load increases, the motor's torque output increases proportionally to the square of the applied voltage, enabling responsive adaptation to changing load conditions.

These characteristics make torque motors especially well-suited for applications that demand constant tension and smooth continuous winding, such as in the textile, paper, plastic, rubber, metal wire, cable, and printing industries. They are ideal for winding products onto reels—like round or flat wire, plastic bags, cling film, and similar materials—where precise tension and speed control are essential.

Features

ü Low starting current with high starting torque

ü 3 Phase squirrel- cage motor with high reliability

ü Torque motor can associate with controller for speed/ torque adjustment

ü Heat dissipation well and long-term operation

Applications

Torque Motor Applications for Winding and Material Handling

Torque motors find versatile applications in winding processes (both center winding and surface winding) and various material handling systems. Here's a breakdown of common uses:

²Winding Applications: Web Handling of Flexible Materials: Ideal for winding and unwinding fabric, plastic bands, rubber bands, fabric bands, and paper bands. This includes processes in textile manufacturing, packaging, and printing.

- Wire and Filament Winding: Used for precise tension control in winding thread, copper wire, iron wire, aluminum wire, insulating electric wire, and plastic string. This is crucial in coil winding, cable manufacturing, and fiber processing.

²Integration with Processing Machinery: Extrusion Lines: Can be integrated with PP & PE monofilament making machines, monofilament extrusion lines, and blown film extruders for consistent material take-up.

- Slitting and Weaving: Utilized in slitting machines and circular looms for accurate web tension control.

- Textile Processing: Applicable in machinery like desizing machines, and in dyeing and printing fabrics where consistent material feed is required.

²Material Handling and Auxiliary Functions: Crushing and Recycling: Can power the feeding mechanisms of powerful crusher machines.

- Load Management: Used as load auxiliary, for starting or braking mechanisms, and in systems for receiving and distributing material.

- Tension Control: Employed as a compensator in web handling systems to maintain consistent tension.

- Automation and Inspection: Integrated into braking and feeding devices, as well as with cloth inspecting machines and lifters for automated material movement and quality control.

Motor No. of Pole Synchronous RPM & Torque